How does a small engine governor work?

The governor system is like a cruise control system. It maintains the speed of your lawn mower or outdoor power products. When Briggs & Stratton governors are adjusted properly, they keep your speed steady regardless of engine load - the amount of work the engine must perform.

When powering a lawn mower, engine load can be affected by hills or height of grass. For a tiller engine, load may depend on depth of the tines while a chipper’s load may be affected by the thickness of branches.

Without a governor, you would need to adjust the throttle manually each time your lawn mower ran across a dense patch of grass. A governor does the job for you by detecting changes in the load and adjusting the throttle to compensate.

Types of Governor Systems

Your small engine contains either a pneumatic governor or a mechanical governor. The main difference between the two is how they detect speed.

How Mechanical Engine Governors Work

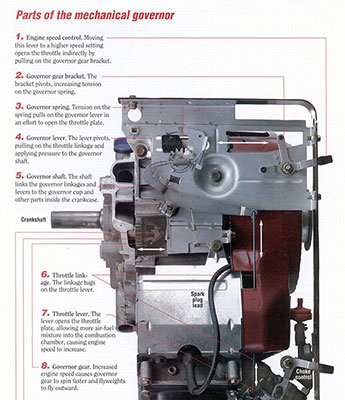

To control engine speed, a mechanical governor uses gears and flyweights inside the crankcase to detect changes in the load and adjusts the throttle accordingly.

If you're operating your small engine under a light load, the carburetor needs to deliver a relatively small amount of air-fuel mixture to the combustion chamber. This is all controlled by the crankshaft - which spins quickly under a light load and slowly when the engine is working harder.

When the crankshaft spins quickly, the flyweights open up, putting pressure on the governor cup and crank. This closes the throttle, limiting the air-fuel released into the engine.

When the engine load increases, the crankshaft spins more slowly. This leads the flyweights to relax and the throttle to open back up. Governor springs hold the throttle in the desired maximum speed.

How Pneumatic Engine Governors Work

The speed-sensing device on a pneumatic governor is a movable air vane, made of metal or plastic. This small engine part registers the change in air pressure around the spinning flywheel.

The pneumatic governor also relies on one or two springs to pull the throttle toward the open position. As the load lessens and engine speed increases, air blown by the flywheel also begins to increase, causing the governor blade to pull the throttle plate toward the closed position in its effort to maintain a steady engine speed. The pneumatic governor design is simpler and parts are easier to access.

More questions about small engine governors for lawn mowers & outdoor power products?

Find out if your lawn mower or outdoor power product uses a mechanical or pneumatic governor in your engine manual.

Contact a Briggs & Stratton dealer near you for one-on-one help!