BRIGGS & STRATTON TRAININGS

Empowering Service Excellence With Ease

As a global leader in power solutions, Briggs & Stratton is dedicated to keeping the machines that depend on them running at their best through a knowledgeable and motivated dealer network. By upholding the highest standards of service and support, we strive to deliver outstanding customer satisfaction while making repair and warranty processes as seamless as possible for our partners.

Why Attend Our Trainings

Learn straight from the experts:

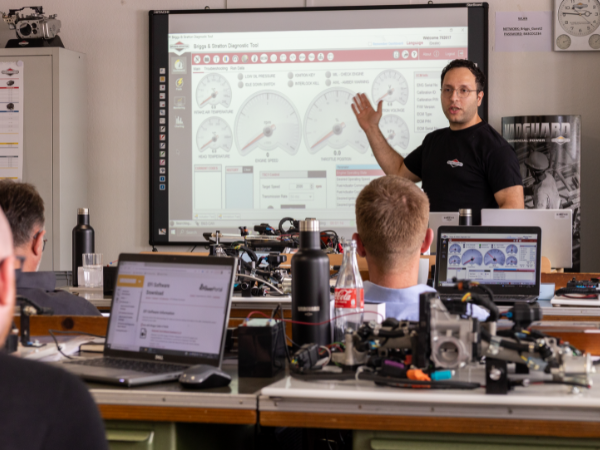

Get hands-on knowledge from the technicians who know our engines inside and out with practical insights you won’t find in other courses.

Keep up with new technology:

Stay informed about the latest technical developments, tools and service methods before they even become an industry standard.

Earn customer trust and stand out:

Official training from the manufacturer shows your professionalism and builds confidence in your expertise, skills and technical advice.

Work smarter and grow your business:

Skilled teams work more efficiently, provide better service and help increase customer loyalty, satisfaction and sales.

“The training is worth it. Thank you very much for such a refreshing experience. The knowledge I gained from this training is engraved in my mind."

Thabo Matakalatsa, Cleaning Equipment Manufacturing, South Africa

General Training Information

Each training session typically includes:

Product and technology updates

System knowledge on components and control units

Hands-on practice: working directly on the product, performing measurements, fault diagnostics, and maintenance tasks

Use of diagnostic and special tools for accurate troubleshooting

Service insights including adjustment tips, repair procedures, and spare parts information.

Duration:

Training is usually conducted over one to three full days (6-8 hours per day).

Format:

Courses take place on-site with us directly at our location in Viernheim, Germany, or at our partner training centres located across EMEA, in small groups to ensure personal guidance and qualitative learning.

Certification:

Each participant receives a Briggs & Stratton | Vanguard or partner-issued certificate of participation, confirming their updated technical qualifications.

“As a relative newcomer to the world of garden machinery, I learned a great deal.

The teaching methods were excellent, and the instructor clearly knew his subject matter and was very good at conveying his knowledge."

Jean Pierre Founé, French Dealer

Types of Training

Basic Engine Training

Build a solid foundation in Briggs & Stratton engine technology with this introductory course. Designed for new technicians, it provides a comprehensive overview of engine construction, function, and basic diagnostics. Participants will also gain insight into the current range of Briggs & Stratton engine families and their key features as well as our warranty claim process in the Power Portal.

Target group

Entry-level engine technicians and or dealers wishing to be Briggs & Stratton dealers.

Training content

Engine overview:

- Introduction to 4 stroke theory

- Basic engine construction

- Engine features - How everything works together

- Ignition

- Carburetors

- Lubrication systems

- Model overview and updates on engine groups and their features

- Vertical and horizontal crankshaft engines; single- and twin-cylinder models

- Practical engine work

Practical exercises directly on engines:

- Quick fault detection, especially on carburetors and ignition systems

- Measuring and testing injection systems

- Maintenance and adjustment procedures using diagnostic tools

Additional resources:

- Adjustment and calibration guidelines

- The Power Portal

- Technical data sheets

- Spare parts identification and search

Duration

2 full days (6-8 hours per day).

Engine Failure Analysis

Master the art of engine failure analysis. This hands-on course teaches technicians how to uncover the real causes behind air-cooled engine issues — from overheating and lubrication problems to environmental and application-related factors. Participants will learn how to inspect components, interpret failure patterns, and apply diagnostic techniques to prevent future breakdowns.

Training content

Warranty & Engine Damage:

How to identify valid warranty cases and correctly complete a warranty claim.

Power Portal Deep Dive:

Learn to find technical information, replacement engines

Parts Identification:

Handling challenges in spare part searches and understanding successor engine models.

Duration

Training is usually conducted over one full day (6-8 hours).

Vanguard EFI/ETC Engine Training

Enhance your technical expertise with this advanced training on Vanguard petrol engines featuring EFI (Electronic Fuel Injection) and ETC (Electronic Throttle Control) technology. Participants will gain insight into the structure and function of modern Vanguard engines, including updates on the latest engine families.

Important:

Please bring your laptop for the practical exercises.

Training content

Engine overview:

- Introduction to Vanguard engines

- EFI and ETC engine management systems

- EFI/ETC Fuel injection technology, theoretical foundations

Hands-on practice:

- Diagnostics and measurement techniques on EFI/ETC systems

- Testing injection components and interpreting results

- Maintenance and adjustment procedures using diagnostic tools

- Application of specialised EFI instruments

- Practical troubleshooting on Vanguard Big Block engines and EFI boards

- Practical tips for efficient fault detection and repair

Additional materials

- Adjustment and calibration guidelines

- The Power Portal

- Technical data and specifications

Spare parts search and identification

Duration

2 full days (6-8 hours per day).

Vanguard Li-Ion Battery Training

Deepen your understanding of advanced lithium-ion battery technology. Learn essential knowledge on safety and servicing, explore efficient battery operation, and gain hands-on insights into diagnostics and troubleshooting. The training depends on the knowledge level of the participants and can be basic, intermediate or advanced.

Each training session typically includes

- General information about Briggs & Stratton and the Vanguard battery technology

- Lithium-Ion technology

- Safety

- Battery in Test

- Battery pack in details

- Range of batteries, chargers, motors, controllers

- Battery operation

- Hands-on practice: working directly on the product, performing measurements, fault diagnostics, and maintenance tasks

- Use of diagnostic and special tools for accurate troubleshooting

- Practical knowledge: How to maximize performance and longevity

Duration

The training depends on the knowledge level of the participants and can be basic (4-6 hours total), intermittent (full day - 8-9 hours) or advanced (two days)

“It was a great experience for us to learn about all the innovations. The session was conducted excellently — it was easy to understand and gave us the opportunity for hands-on practice."

Inamullah baig Suhail ahmad, Mona Trading LLC Dubai

Don’t miss out — find your session and register now with just one click!

Grow Your Skills With Our Trainings

For Dealers

If you are a dealer, contact your distributor today to learn about upcoming training opportunities. If no sessions are planned, complete our Training Request Form — we will review it and inform you of new sessions in your region as they become available.

For OEMs

As an OEM, please get in touch with your Briggs & Stratton | Vanguard representative to arrange a training that suits your needs or fill out the Training Request Form. We will review your request and contact you as soon as possible.

“There was a great atmosphere, with a perfect blend of theory and practice.

The training offered a wealth of relevant knowledge and was very helpful overall."

Maximilian Friedrich, Kramp GmbH